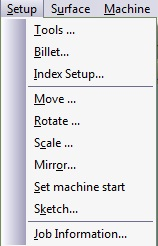

| Setup Menu | ||

|---|---|---|

|

Chapter 5. Mill |  |

Figure 5.17. Setup Menu

|

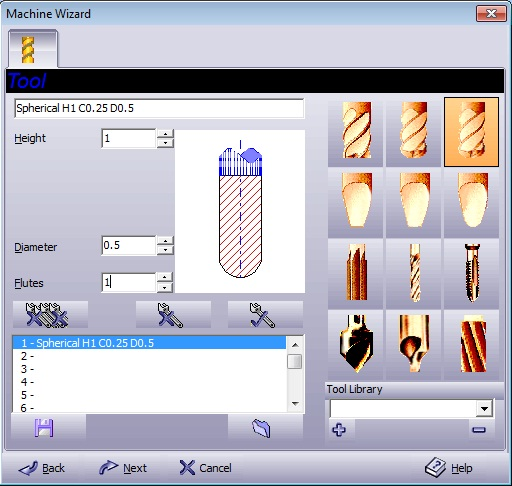

Opens the Tool Library dialog box, and define the tools to be used in the machining process. An engraving tool may have a conical cross section with a nose tip radius and a corner radius. Many kinds of shaped or tapered engraving tools can be defined including flat, ball, and tapered tools. Figure 5.18. Setup Tools Dialogue

|

|

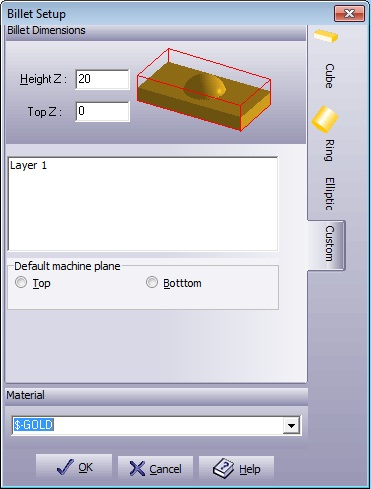

To define the Billet's material, dimensions and location, select from the menu. The following dialog box displays the part you select for the job: Figure 5.19. Setup Cube Billet Dialogue

Figure 5.20. Setup Ring Billet Dialogue

Figure 5.21. Setup Elliptic Billet Dialogue

Figure 5.22. Setup Custom Billet Dialogue

|

|

Change the physical location of any marked group and surface. The following dialog box appears in which you define the Move parameters:

Press to confirm the changes in definition and setup. Press to exit without changes. Press to open the On-line Help. |

|

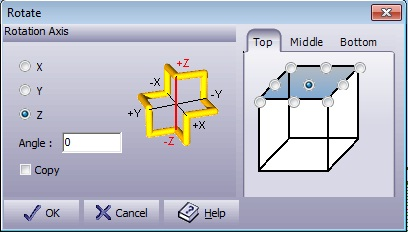

Select from the menu to change the orientation angle of a marked geometry group or surface. Figure 5.28. Setup Rotate Dialogue

Press to confirm the changes in definition and setup. Press to exit without changes. Press to open the On-line Help. |

|

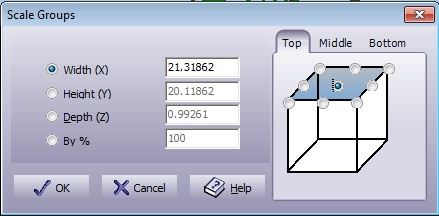

Use the option to change the scale size of a marked group or surface. Mark the group to be scaled and select from the menu. Scale the items manually, by height, width, or percent. Figure 5.29. Setup Scale Dialogue

Press to confirm the changes in definition and setup. Press to exit without changes. Press to open the On-line Help. |

|

Select from the menu to create a mirror image of the marked group or surface. This function is particularly useful for engraving forms for molding. Figure 5.30. Setup Mirror Dialogue

Press to confirm the changes in definition and setup. Press to exit without changes. Press to open the On-line Help. |

|

Specify the location of the chain's new start point. The user thus controls the first point from which the machining process starts. In this mode, the user must click on a new start point for the chain. The command is available only for geometries. The start point of a toolpath depends on the start point of the geometry from which it originates. For open contours, the system will select the nearest edge as the start point. This function is in toggle mode. Select a new command from the menu to cancel this mode. |

|

This function enables quick sketching of a new geometry. It can be used to define an outline or to create a base for manual slotting. Use the Cursor Type dialog box to define the exact cursor position then point and click to create entities. Figure 5.31. Sketch Dialogue

Figure 5.32. Cursor Type Dialogue

|

|

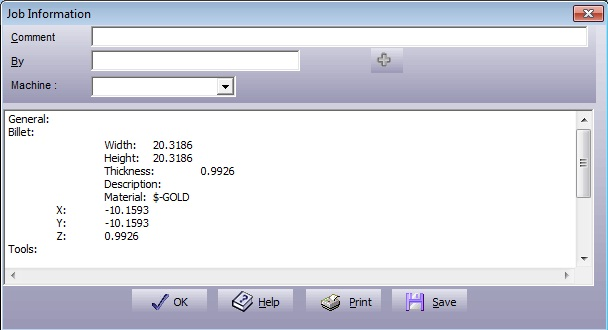

Select from the menu to open the Job Information dialog box and view the list of actions and definitions that applied to the job. You can also add remarks and send the job information report to print. The job information report presents four subjects about your job:

Figure 5.33. Setup Job Information Dialogue  Use the Comment

and By input windows

to create the remarks you want to add to the report, and press the |